- #Servo motor arduino labview driver#

- #Servo motor arduino labview full#

- #Servo motor arduino labview software#

- #Servo motor arduino labview code#

This gives a full step rotation in both clockwise and counter clockwise directions. Full-step mode: The phase switching for the small bipolar stepper motor (Test Setup-I) with full-step, i.e., step angle is shown in Table 1. Both the speed and direction may be changed at any instant by applying the appropriate codes at the stepper motor s signal line. The difference between these two modes is that the application of some of the codes is omitted.

The sequence needed to make the rotor turn can be done in either full step or half step increments.

#Servo motor arduino labview code#

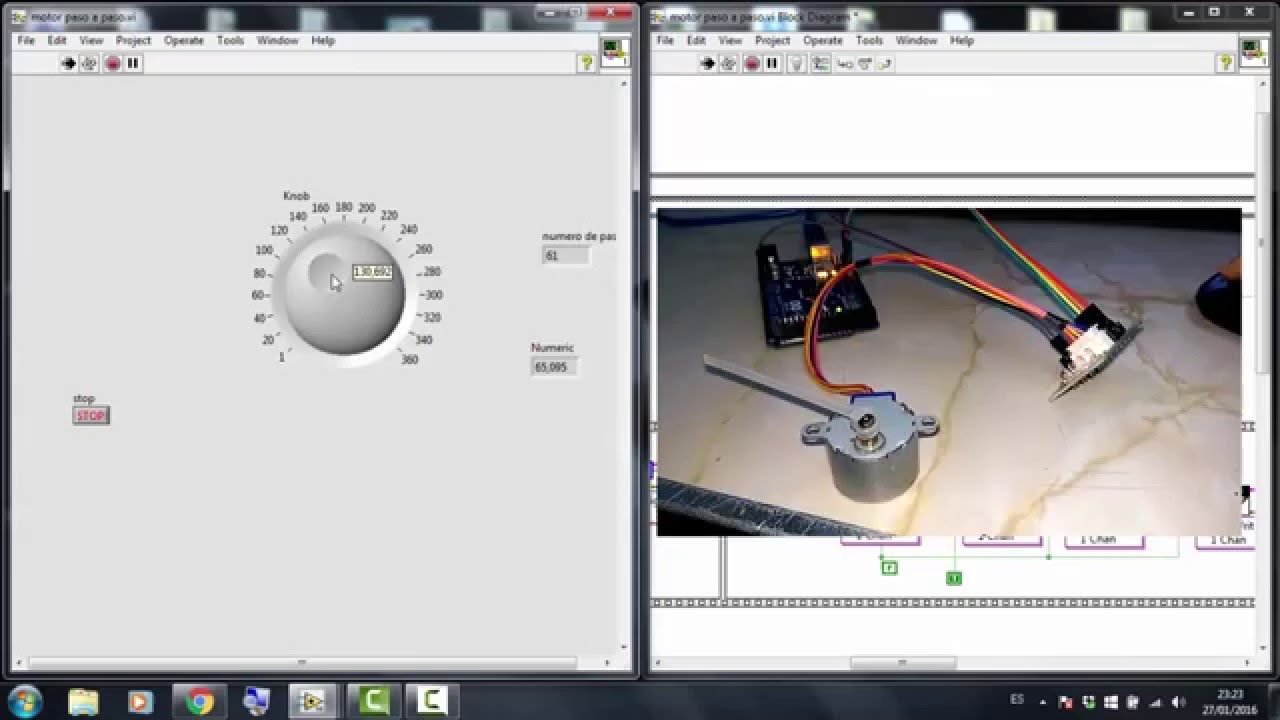

Test Setup-I Stepping Sequence for Full/ Half/ Micro-Steps mode: For a four-coil motor, a four-bit code sequence is needed to energize the appropriate poles at any one time. Actual machining will be done by executing a subroutine for, a) Linear interpolations (G0, G1) b) Circular interpolations (G2, G3) c) Engraving operations (A-Z and 0-9) which utilize (a) and (b) 4. 2ģ An interfacing circuit board will be built based on the stepper motor in order to interface between the controllers (PC) and the CNC milling machine. The new controller will be applied to an existing milling machine, which is the CNC milling machine by replacing the existing servo-motor controller with the new controller. The LabVIEW Program is built based on the basic G-codes, which are G0, G1, G2 and G3. Scope of the Research The controller will be built using LabVIEW TM, a graphical programming language produced by National Instruments of Austin, TX, USA. To develop a LabVIEW program that can generate machine command from basic CNCcode.

#Servo motor arduino labview driver#

To develop a driver and an interface circuit between the CNC machine and a PC. To replace the existing servo motors with stepper motors control system for the desktop CNC milling machine. Objectives Figure 2-Motor and Lead screw Arrangement 3 The main objectives of this research are: 1.

Test setup II: To apply the knowledge of LabVIEW and stepping sequence in operating the X and Y axes motion of CNC miniature mill for the engraving operation using ballscrew slides and appropriate stepper motors. Figure 1-A Small Stepper Motor Purchased from Danaher Motion 2 2. Test setup I: Build a stepper motor driver interface and control a small 2-phase, bipolar stepper motor using LabVIEW through digital output of a DAQ (Data Acquisition) card for full, half and micro-stepping in both clockwise and counter-clockwise directions. The work is covered mainly in two steps: 1. 1Ģ In this work, the servo motors used in the CNC miniature mill are replaced by stepper motors mainly due to their high holding torque at low speeds, their excellent precise positioning mechanism, their simple open-loop feedback system applications and their lower cost.

#Servo motor arduino labview software#

So basically, a close-loop feedback system was used to drive the ballscrew slides for X and Y axis movements using several subroutines and the software library provided by Technology 80 for a Model 5650 controller card 1. In this CNC project, DC brush servo motors were used as a conventional motor technology to produce rotary motion in response to an applied voltage. 1 successfully designed and manufactured a fully operational desktop CNC milling machine under the guidance of Dr. LabVIEW TM is a graphical programming language produced by National Instruments of Austin, TX, USA. The basic CNC code included linear and circular interpolations, which provide the foundation necessary for the implementation of any future design expansion of the program. The program also controls the basic functions of the desktop CNC mill, such as turning the spindle on and off and controlling travel limits of the worktable. The aim of this paper is to utilize stepper motors, build their control circuit and write a LabVIEW TM program that reads and implements a CNC code, in the form of a text file, for engraving operations on a desktop mill. Cherif Aissi Department of Industrial Technology University of Louisiana at Lafayette Lafayette, LA, USA Abstract The advantage of stepper motor motion control system in a computer numerically controlled (CNC) desktop mill is the high holding torque at low speeds. Elsayed Department of Mechanical Engineering University of Louisiana at Lafayette Lafayette, LA, USA Dr. 1 Session G-19 STEPPER MOTOR CONTROL USING LABVIEW TM IN A COMPUTER NUMERICALLY CONTROLLED DESKTOP MILL Usha L Manepalli, Dr.

0 kommentar(er)

0 kommentar(er)